Roar Solutions - Truths

Roar Solutions - Truths

Blog Article

What Does Roar Solutions Do?

Table of ContentsFascination About Roar Solutions5 Simple Techniques For Roar SolutionsRumored Buzz on Roar SolutionsThe 5-Second Trick For Roar Solutions

The devices register is an extensive data source of devices documents that consists of a minimum set of fields to determine each product's area, technological specifications, Ex lover category, age, and ecological data. This details is critical for tracking and handling the devices effectively within dangerous locations. In comparison, for regular or RBI tasting inspections, the quality will be a combination of Detailed and Close examinations. The ratio of Detailed to Close examinations will be established by the Devices Threat, which is assessed based on ignition threat (the probability of a source of ignition versus the chance of a flammable ambience )and the hazardous area category( Zone 0, 1, or 2). This variation will certainly likewise influence the resourcing requirements for work preparation. As soon as Whole lots are specified, you can develop tasting plans based upon the sample dimension of each Lot, which describes the variety of arbitrary devices items to be examined. To establish the called for example dimension, two aspects need to be evaluated: the size of the Lot and the classification of evaluation, which shows the degree of initiative that must be applied( decreased, regular, or boosted )to the inspection of the Whole lot. By incorporating the category of evaluation with the Great deal size, you can then establish the appropriate denial criteria for a sample, meaning the allowed variety of defective products discovered within that sample. For more details on this procedure, please describe the Power Institute Standards. The IEC 60079 standard advises that the maximum period between inspections need to not surpass 3 years. EEHA assessments will likewise be performed outside of RBI projects as part of scheduled maintenance and equipment overhauls or fixings. These evaluations can be credited toward the RBI example sizes within the influenced Lots. EEHA examinations are performed to determine mistakes in electrical tools. A heavy scoring system is necessary, as a single tool might have several mistakes, each with differing degrees of ignition danger. If the mixed rating of both inspections is less than twice the fault score, the Great deal is regarded acceptable. If the Great deal is still thought about unacceptable, it should go through a complete examination or justification, which may activate stricter assessment protocols. Accepted Great deal: The root causes of any type of faults are determined. If a common failure mode is located, added tools may call for assessment and fixing. Faults are identified by intensity( Safety and security, Stability, Housekeeping ), guaranteeing that immediate issues are examined and dealt with quickly to reduce any type of effect on safety or operations. The EEHA data source ought to track and tape the lifecycle of mistakes together with the restorative activities taken. Carrying out a robust Risk-Based Inspection( RBI )technique is critical for making certain conformity and safety and security in taking care of Electric Devices in Hazardous Areas( EEHA). Automated Mistake Scoring and Lifecycle Monitoring: Effortlessly manage mistakes and track their lifecycle to enhance assessment accuracy. The intro of this support for risk-based inspection even more enhances Inspectivity's placement as a best-in-class remedy for regulatory conformity, as well as for any asset-centric assessment use case. If you want discovering more, we welcome you to ask for a demo and find just how our service can transform your EEHA monitoring processes.

With over one decade of consolidated Ex-spouse experience (IECEx/ATEX, EEHA), Saipex began to advertise the relevance of capability of all employees included in the Hazardous Location area in 2019. In 2021, our partnership with IndEx and Tech Skill International (TSI) marked a turning point in the Saipex road to proceed Ex lover renovation.

How Roar Solutions can Save You Time, Stress, and Money.

In terms of eruptive risk, a dangerous area is an atmosphere in which an eruptive atmosphere exists (or may be expected to be present) in quantities that need special safety measures for the building, installment and use tools. In this write-up we explore the difficulties encountered in the work environment, the threat control procedures, and the called for proficiencies to work securely.

(https://roar-solutions-48388330.hubspotpagebuilder.com/roar-solutions/master-hazardous-area-safety-with-eeha-certificate-training)

These compounds can, in certain conditions, form eruptive environments and these can have major and awful consequences. Most of us are acquainted with the fire triangular eliminate any type of one of the three elements and the fire can not take place, however what does this mean in the context of harmful locations?

This is then validated via inspection and testing and is preserved throughout the life of the installment by employing the appropriate maintenance methods, supplemented by routine examination. When all these actions are taken, they should also be documented. The verification file consists of info such as the dangerous area classification illustration, makers' paperwork, equipment accreditation, design illustrations and computations, examination records, and documents of an individual's competency and proceeding professional growth (CPD), such as through ECA's eCOMS software.

How Roar Solutions can Save You Time, Stress, and Money.

It is imperative that trainees understand and have a complete expertise as to just what comprises a dangerous area. The pupil needs to additionally recognize why training is essential before attempting to take on job or defining devices into an unsafe location. These areas are additionally called categorized places and are specified as areas which have a high chance of an explosion due to the possible existence of combustible gases, vapors, dusts and so on.

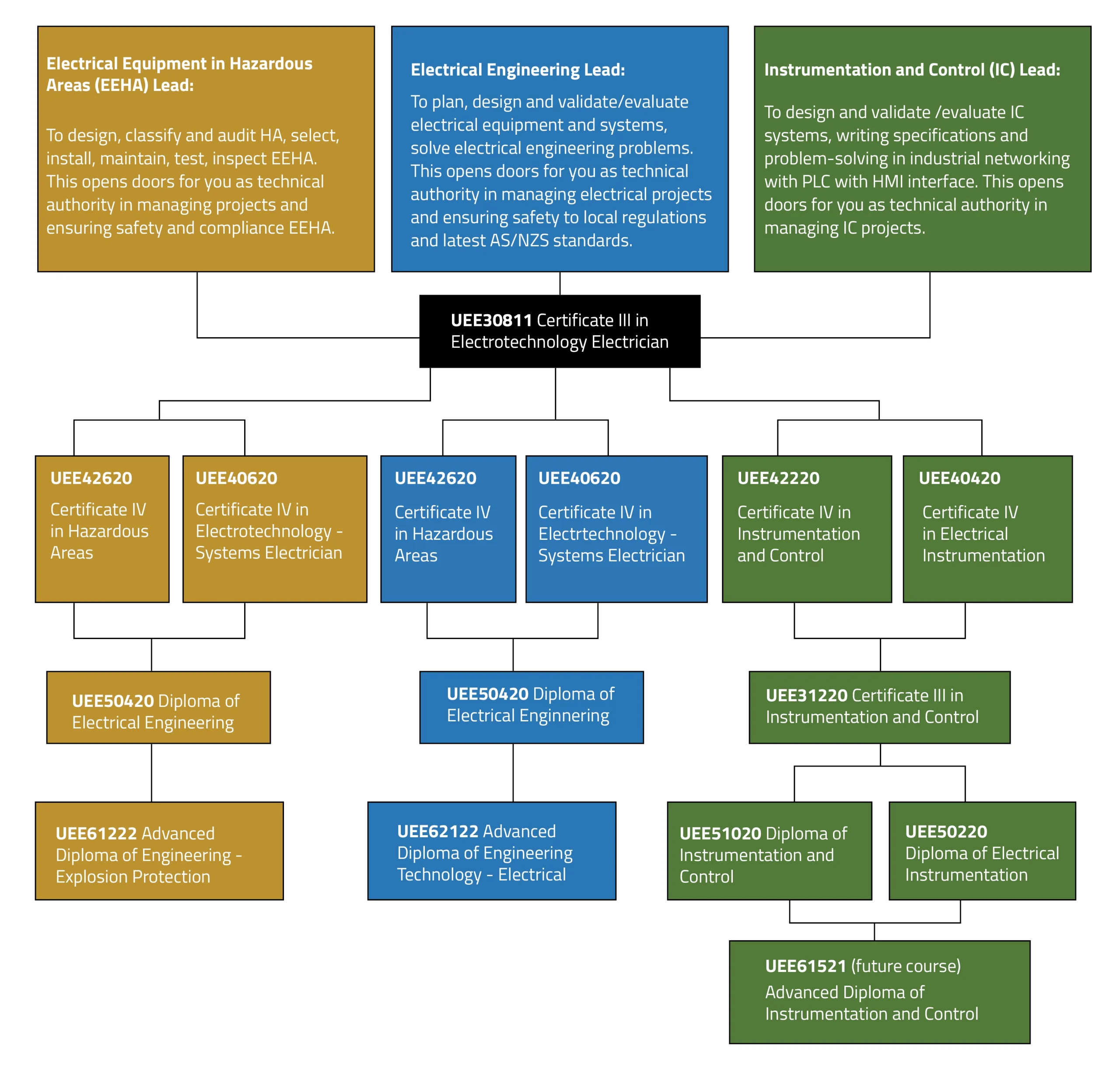

Industries which contain unsafe areas are currently demanding that electrical employees that are specifying or operating in these locations ought to have an unsafe area qualification that regards them experienced. Jobs in these markets are really satisfying so you need to be prepared. To meet this demand for the industry, across the country identified training in Certification IV in Hazardous area Electrical and EEHA training on the advancement of experienced specialists.

5 Simple Techniques For Roar Solutions

Tech Abilities Australia is a Registered Training Company supplying you with the most affordable and quickest method getting your credentials - hazardous area course. Our instructors are sector certified and have numerous years of procedure experience. Our programs have actually assisted thousands of individuals from business managers to everyday workers in acquiring a solid hang on this not so difficult but high threat training

The training also consists of recognizing the unsafe areas, resources of explosion and the homes of hazardous products along with the responsibilities and features of all parties, regulations, systems, standards and method codes linked to dangerous areas. We give instrumentation and hazardous location services that are in compliance visit this site to most current AS/NZS and worldwide sector standards.

Report this page